1. Wiring of Main (Power) Terminals ⚡

- Input Power: Connect 3-phase lines to L1/R, L2/S, L3/T. For single-phase, use L1/L and L2/N.

- Motor Output: Connect U, V, W to the motor. Swap two wires if rotation is incorrect.

- Grounding: Use G terminals for chassis and motor ground. Essential for safety and noise suppression.

- For motors >50 m away, use an output filter to reduce leakage currents.

2. Control Circuit & Command Inputs

a) Power Supply

- P(+)/N(–): DC 24V input for the control board or brake chopper connections.

b) Digital Inputs

- X1–X5, FWD, REV: Digital inputs configured via function codes.

- Default mode: PNP/source; change using switch SW1.

- Connect to CM for return signal.

- Use EN1/EN2 terminals to enable external control.

c) Analog Inputs

- Terminals 11, 12, 13 used for potentiometers or 0–10 V control.

- Set F01 = 1 to use analog mode; H30 = 0 for analog control over Modbus.

d) Relay Outputs

- 30A–30C: Default function is fault output; configurable via E27.

e) Transistor Outputs

- Y1, Y2, Y5, etc., used for external device control (brakes, alarms).

3. Brake Resistor and DC Link

- Use B1/B2 or P(+)/DB for dynamic braking.

- Required for heavy or regenerative loads.

- Screened cable must be grounded at both ends.

4. Programming Key Parameters

- F00: Parameter lock

- F01: Speed reference (0 = keypad, 1 = analog, 4 = internal pot)

- F02: Run control (0 = keypad, 1 = terminal)

- F03–F08: Max frequency, base freq, accel/decel time

- F11: Rated current

- F15/F16: Frequency upper/lower limits

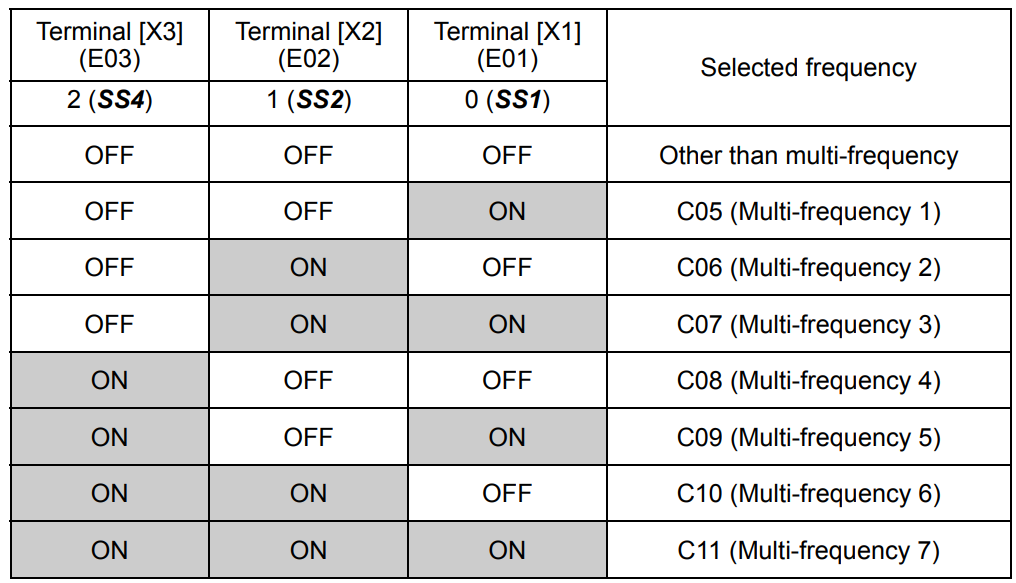

Multi-Step Speed

- Assign X1–X3 to E01–E03

- Set speeds C05–C09

5. Modbus RS‑485 Communication

- Set H30 = 3 or 8 depending on control mode.

- Set Y01–Y10 for slave address, baud rate, parity, etc.

- Use Hex 705 for frequency, Hex 706 for run/stop control.

6. Example Wiring Schematics

Basic Start/Stop

- Wire X1 to start, CM as return. Set F02 = 1.

Multi-Step Speed

- Use X1–X3 to select preset speeds via C05–C07.

Hybrid Modbus + Digital

- Use H30 = 8 for auto switching between Modbus and terminals.

7. Best Practices and Safety

- Use ferrules on all control wires.

- Separate power and control lines.

- Shielded cable for analog; ground shield at one end only.

8. Troubleshooting

- Reverse motor: swap U/V/W or change logic.

- Inputs not responding: verify PNP/NPN logic and assignment.